Tube Furnace Manufacturers

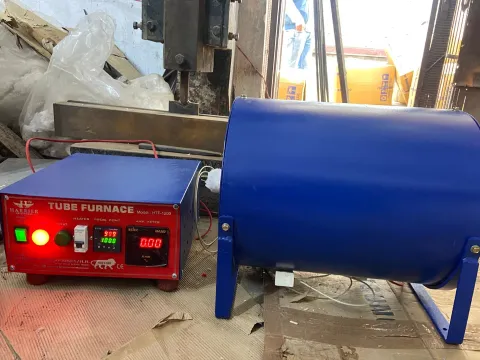

We are the best Tube Furnace Manufacturer and supplier. This is a type of high-temperature furnace designed with a cylindrical chamber (tube) made of materials like quartz, alumina, or ceramic. Tube Furnace valued for their ability to heat samples. This Tube Furnace is mainly used in laboratories and industries for their thermal process in controlled atmosphere. It is capable of reaching temperatures up to 1200°C–1800°C depending on model capacity. This Tube Furnace comes in horizontal or vertical configurations, and are available with single, two zone, three zone or multi-zone heating for complex thermal gradients. Modern tube furnaces are equipped with digital programmable controllers that allow users to set precise temperature profiles and ramp rates for various heating cycles.

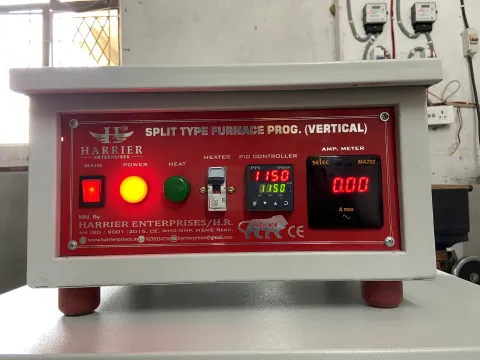

Tube furnaces are available in single-zone, multi-zone, split-type, and rotary configurations, tube furnaces offer flexibility for different experimental needs. The split design allows easy loading and cleaning, while multi-zone models help create temperature gradients for advanced research.

Features Of Tube Furnace:

High-temperature operation up to 1800°C for advanced thermal processes.

Programmable PID controller for precise temperature control and ramp/soak profiles.

Uniform heat distribution around the sample due to cylindrical heating design.

Atmosphere compatibility with inert gas, reducing gas, or vacuum environments.

Multiple tube material options like quartz, alumina, or ceramic based on application.

Split and horizontal/vertical designs for easy access and flexible setup.

Our Products

Working Principle of Tube Furnace:

A Tube Furnace operates on the basic principle of resistive heating, where electrical energy is converted into heat energy through high-resistance heating elements. These heating elements, typically made of materials like Kanthal, molybdenum disilicide (MoSi₂), or silicon carbide, are arranged around a cylindrical heating chamber that houses the tube.

Step-by-Step Working Principle:

- Electric Heating Elements Activation: When power is supplied, the heating elements generate heat through electrical resistance.

- Heat Transfer to the Furnace Tube: The heat is transferred by radiation and conduction to the furnace’s inner chamber and to the tube placed inside it. The tube contains the material/sample to be processed.

- Temperature Control: A programmable temperature controller regulates the heating cycle. It monitors the temperature via thermocouples and adjusts the power to the heating elements to maintain the desired setpoint.

- Atmosphere Control (Optional): For specialized applications, gases like argon, nitrogen, hydrogen, or vacuum are introduced into the tube. This protects the sample from oxidation or enables chemical reactions under controlled environments.

- Thermal Processing: The sample inside the tube undergoes processes like calcination, annealing, sintering, or material synthesis under uniform and stable temperature conditions.

We manufactured quality products to offer durability, reliability and best performance to our clients. If you are searching for a Tube Furnace manufacturer, we are here to provide you the best Tube Furnace as per your needs. We are also a manufacturer and supplier of Muffle Furnace. Tube Furnace plays an essential role in materials science, nanotechnology, ceramics, and semiconductor industries. Their ability to deliver consistent, high-precision thermal processing makes them a vital tool for researchers and manufacturers working with advanced materials.

We are able to design customized furnaces according to the customer’s requirements such as controlled atmosphere capabilities (vacuum or inert gas), different tube materials (quartz, alumina, Inconel), and integration with gas flow or data logging systems. Whether for educational labs or industrial R&D, a reputable tube furnace manufacturer ensures high performance, durability, and safety making them a trusted partner in precision thermal processing.